Popular and versatile as well screen printing and digital printing each have their own advantages and disadvantages that make them ideal for different types of printing. The purpose of this article is to help you in making the correct selection for your project by explaining the main distinctions, advantages, and disadvantages of each technique. Now, let’s explore printing in depth!

Table of Contents

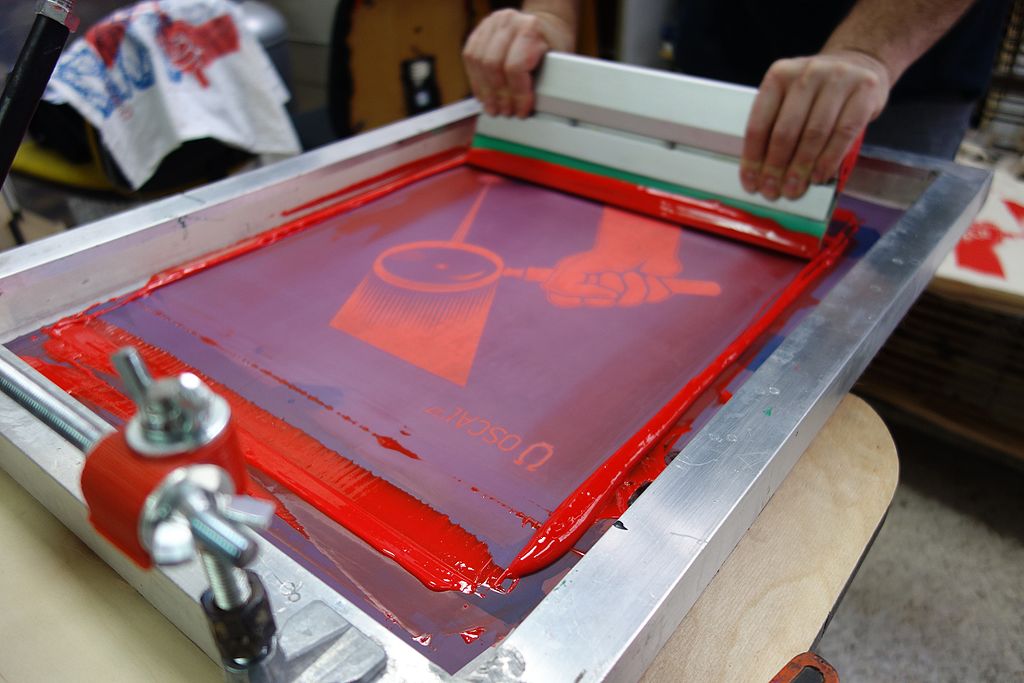

ToggleWhat is Screen Printing?

Screen printing involves using a stencil known as the screen. It is used to apply layers of ink to a surface one at a time. Each color requires a separate screen. The process starts by creating a stencil on a fine mesh screen, often made of polyester or silk. you can read also How Much Does a Cardboard Box Weigh?

Ink is pushed through the open surface of the stencil on the surface underneath. This step is repeated with various screens, each featuring a unique design and color. After the final image is complete, the printed material is exposed to UV lights to cure the ink instantly.

What is Digital Printing?

Digital printing is a contemporary process involving advanced computing. In this method, the image on the screen is analyzed and converted into a printable format directly onto the desired surface. Digital printing relies on a computer and digital files to position tiny ink droplets, forming the image.

There are two main types: roll printing, which uses flexible vinyl, and flatbed printing. It offers versatility by printing on both flexible and rigid surfaces. Digital printing can use UV light, solvent, or inkjet printing. It provides a more adaptable and efficient approach compared to traditional printing methods. You can also read this guide for more Knowledge What is the Correct Way to Read Product Dimensions?.

Uses of Screen Printing

Screen printing has wide applications in plastics, textiles, and latex. Its versatility extends to products like clothing, balloons, and wallpaper. This method is ideal for surfaces not requiring pressure. Industries use screen printing for vibrant and durable prints on various materials.

Uses of Digital Printing

Digital printing is ideal for direct mail, coupons, and projects requiring a crisp and modern finish. Its detailed capabilities make it versatile for personalized prints on various items. It offers efficiency in producing intricate designs. Digital printing is utilized for its adaptability in different printing applications. If you have any query you can contact with Packpaa.

Screen Print Vs Digital Print: The Key Differences

Screen printing and digital printing represent two distinct methods in the world of printing, each offering unique characteristics and catering to specific needs. The fundamental difference lies in their processes, impacting factors such as setup, quantity, color payoff, print complexity, and adhesion.

Setup and Process:

- Screen printing involves creating a stencil on a fine mesh screen. This manual process demands the creation and setup of screens for each color, adding one-time fees and high setup costs.

- Digital printing uses computers and digital files to print. It makes digital printing a more efficient and cost-effective option for smaller quantities. you may also like to read How Much Does a Box of Paper Weigh

Quantity and Speed:

- Screen printing becomes cost-effective for large quantities as setup costs are divided over numerous prints. The speed of screen printing is more than that of digital printing for high-volume prints.

- Digital printing shines in low-quantity prints due to its low setup fees. It offers a quicker turnaround, making it suitable for projects that require quick delivery.

Color Payoff and Print Complexity:

- Color accuracy is a critical distinction. Screen printing uses spot colors like Pantone Matching System (PMS). It allows vibrant and precise color reproduction. Screen printing excels in simple designs.

- Digital printing uses a CMYK four-color process. It has some limitations in color range compared to screen printing. Digital printing is better suited for intricate images, gradients, and detailed prints and photographs.

Adhesion and Durability:

- Screen Printing: More durable and weather-resistant, ideal for longevity and adherence to various surfaces.

- Digital Printing: Less durable, with potential adhesion challenges on certain surfaces.

Read More: Frustration-Free vs Standard Packaging

Digital Print Vs Screen Print: Benefits and Drawbacks

Benefits of Screen Printing:

– Vibrant Colors: Offers high color vibrancy and saturation.

– Durability: Ensures long-lasting and robust prints.

– Versatility: Suitable for various materials and surfaces.

– Cost-Effective for Large Quantities: Becomes economical for bulk orders.

– Specialty Products: Ideal for printing on different items like apparel, mugs, and more.

Also Check This Guide: Lego Frustration-Free Packaging

Drawbacks of Screen Printing:

– Setup Costs: Involves high setup fees, making it less cost-effective for small volumes.

– Time-Consuming Setup: Requires separate screens for each color, extending setup time.

– Limited Detail: Not suitable for complex designs and fine details.

Benefits of Digital Printing:

– Quick Turnaround: Offers a faster printing process and is suitable for small deadlines.

– High Detail: Excels in reproducing intricate designs and photographic prints.

– Variable Data Printing: Enables customization and personalization in each print.

– No Setup Fees: Eliminates one-time setup costs and makes it cost-effective for small runs.

Drawbacks of Digital Printing:

– Color Limitations: Might have limitations in reproducing vibrant colors.

– Material Restrictions: Adhesion challenges on certain surfaces.

– Durability: Generally less durable compared to screen printing, especially for outdoor use.

– Cost for High Quantities: Becomes less cost-effective for large quantities due to slower production speed.

Understanding these pros and cons can help to choose the most suitable printing method based on specific project requirements and priorities.

Read Our Latest Guides:

Final Words

Screen printing and digital printing each have their strengths and weaknesses. Screen printing stands out for vibrant colors, durability, and versatility but comes with setup costs and limited detail. Digital printing offers quick turnarounds, high detail, and no setup fees, yet may have color limitations and be less durable.

Choosing between them depends on your project’s specifications – whether it’s a large quantity with vibrant colors (consider screen printing) or a small, detailed run with quick turnaround needs (opt for digital printing). Understanding these differences will help you make the right decision for your printing project.

FAQs:

A: It depends on your specific needs. Digital printing offers high detail and quick turnaround for small runs, while screen printing provides vibrant colors and durability for larger quantities.

A: Screen printing generally lasts longer due to its durable ink and adhesion to surfaces. Digital printing may be less durable, especially for outdoor use.

A: Digital printing is typically cheaper for small quantities due to lower setup costs. However, for larger quantities, screen printing becomes more cost-effective as setup costs are divided over numerous prints.

A: Screen printing often provides better quality in terms of vibrant colors and precise color reproduction, especially for simple designs.

A: Digital printing may have limitations in reproducing vibrant colors, and it can be less durable compared to screen printing, especially for outdoor applications.

Meet Mary K, the talented author behind PackPaa. With a passion for innovative packaging solutions, Mary shares insights and expertise to elevate your business.